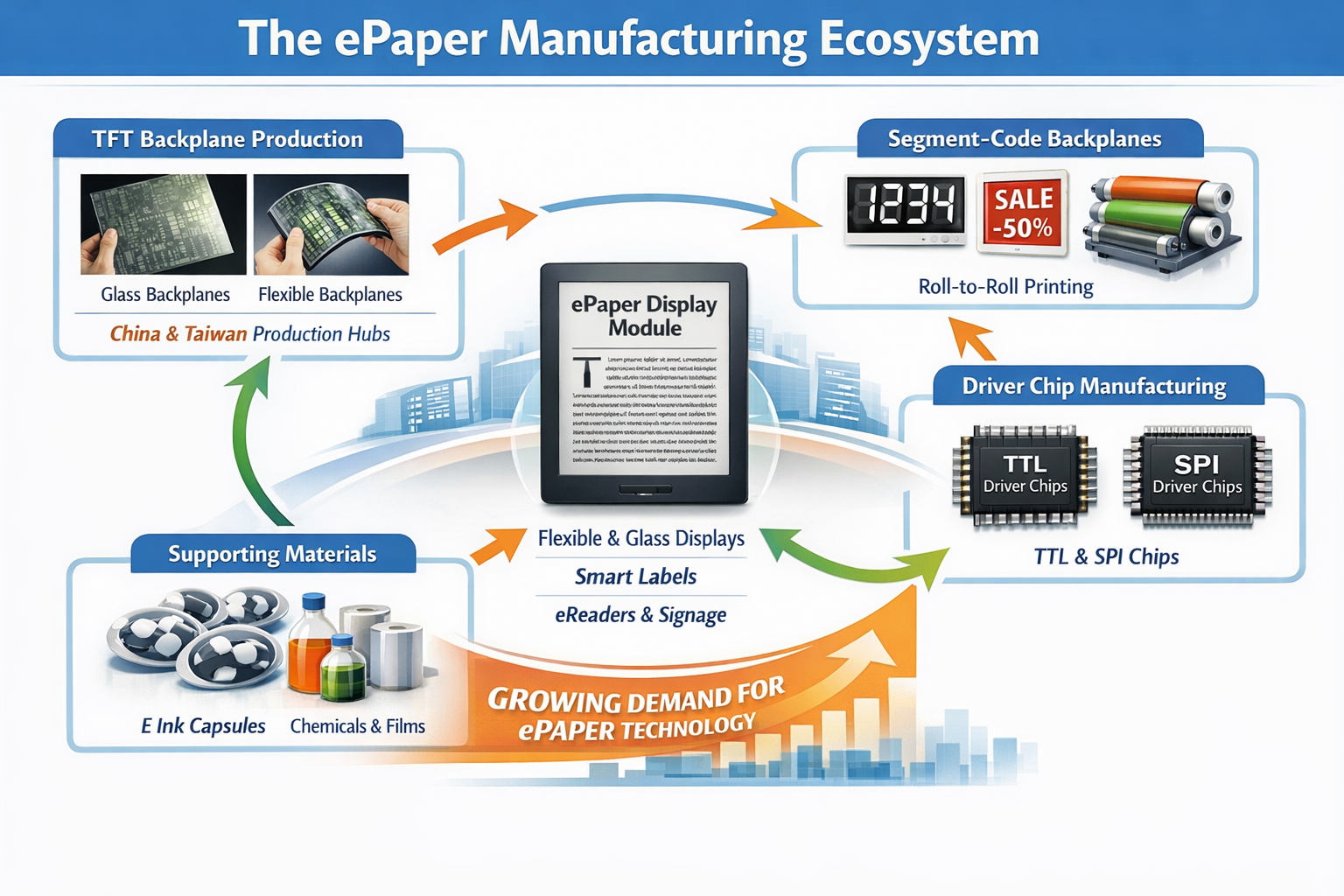

The ePaper industry has been growing rapidly, driven by advances in technology and the increasing demand for flexible, low-power displays. From e-readers to smart labels, ePaper technology is now integral to many sectors, including retail, advertising, and consumer electronics. The industry itself can be broken down into two major segments: ePaper manufacturing and ePaper application. Both segments are closely linked by the production of ePaper display modules, which act as the core of many innovative digital products. In this article, we will explore the components of the ePaper manufacturing chain, including key technologies such as TFT backplanes, segment-code backplanes, drive chips, and the supporting materials used in the production process.

The ePaper Manufacturing Ecosystem: Key Players and Technologies

The ePaper manufacturing chain includes several critical components, each playing an important role in producing high-quality ePaper displays. These components consist of TFT backplane manufacturers, driver chip manufacturers, and various supporting materials suppliers. Let’s take a closer look at each of these elements.

- TFT Backplane Technology

Just like LCD (liquid crystal display) technology, ePaper displays use Thin Film Transistor (TFT) backplanes, which manage the pixels and display content. The material used for these backplanes can be either glass or flexible substrates, depending on the application.

TFT glass backplanes for ePaper devices are produced using similar processes to those used in LCD production, making them a part of the shared manufacturing ecosystem. On the other hand, flexible ePaper uses polyimide (PI) thin films as a substrate, which are shared with flexible AMOLED displays. This flexible nature is one of the key selling points of ePaper, as it allows for curved displays and other flexible applications.

Currently, ePaper backplane manufacturers are concentrated in regions such as mainland China and Taiwan. These regions have seen increased investments in TFT backplane production to meet the growing demand for ePaper products. The market for ePaper displays remains smaller than the LCD market, but it is steadily growing. For smaller ePaper devices (typically 13.3 inches or smaller), production uses G4.5 to G6-generation lines, while larger devices (above 25.3 inches) use G8.5-generation lines.

- Segment-Code Backplanes

In addition to the standard TFT backplanes, another type of backplane used in specific applications is the segment-code backplane. These are commonly found in applications where simple patterns or text, such as seven-segment displays, are used. Segment-code backplanes are typically made with flexible printed circuits (FPC), screen printing, or conductive ink technologies.

Roll-to-roll conductive ink printing offers unique advantages, such as multi-layer circuit construction without the need for vias, and enhanced waterproofing capabilities. This makes segment-code backplanes an attractive option for applications in digital signage or smart labels that require high durability and easy scalability.

The Role of Driver Chips in ePaper Displays

Driver chips are one of the most essential components in ePaper display modules. They are responsible for managing the timing and control signals that drive the pixels on the screen. The driver chip market for ePaper can be broadly classified into two categories:

- TTL (Parallel Interface) Driver Chips: These are commonly used in eReaders and other devices with high-performance display requirements.

- SPI (Serial Peripheral Interface) Driver Chips: These driver chips are primarily used for electronic shelf labels (ESL) and other low-cost, large-scale applications. SPI driver chips are more popular, accounting for over 95% of the market due to their integrated design, which eliminates the need for an external timing control (Tcon) chip.

The shift towards SPI driver chips has made ePaper technology more accessible and cost-effective for a wide range of industries. All-in-one driver chips combine the Tcon, power management, and temperature detection functions into a single chip, making them ideal for low-power applications such as smart tags and digital signage.

Supporting Materials for ePaper Production

Beyond the core components, ePaper production relies heavily on a variety of supporting materials, which contribute to the display’s durability, functionality, and cost-effectiveness. These materials include:

- Adhesives: A range of specialized adhesives, such as conductive silver glue, anisotropic conductive glue, and UV glue, is used to bind different layers of the display module. For example, edge-seal adhesives are essential for sealing the edges of the ePaper module to prevent moisture ingress.

- Protective Films (PS): Protective films are applied to the surface of the ePaper to ensure scratch resistance and durability.

- Flexible Circuit Boards (FPC): These are used to connect various components of the ePaper module and allow for flexible display solutions.

- Capacitive Touch Panels and Other Components: As the demand for interactive ePaper solutions grows, touch panels and flexible circuits are becoming more common in applications like interactive kiosks and eNote devices.

The development and iteration of these materials play a critical role in improving the overall production process, increasing yield rates, and reducing manufacturing costs.

SEEKINK: Innovating the Future of ePaper Technology

We are at the forefront of the ePaper industry, providing high-performance ePaper modules and ODM solutions that enable leading brands to develop their own electronic shelf labels, digital displays, and consumer devices. One of our representative products, the H82EPL 8.2-inch E-Ink Reader, demonstrates our expertise in delivering large-screen, low-power, and highly readable ePaper solutions. This device offers a natural, paper-like reading experience with enhanced comfort for long-term use and supports applications such as e-reading, digital note-taking, and portable content display. Powered by SEEKINK’s proprietary 8.2-inch EPD module, the H82EPL also allows high customization for brands through our e-ink solutions, making it a versatile choice for both consumer and commercial applications.

Beyond consumer devices, our ePaper technology powers a wide range of applications through collaboration with brands and system integrators. With deep expertise in flexible displays, high-performance driver chips, and customized ePaper solutions, we help partners bring innovative ePaper products to market efficiently and reliably.