As the demand for high-performance, low-power displays continues to grow, electrowetting ePaper technology has emerged as a groundbreaking solution for dynamic and vibrant digital signage. This technology, offering rapid response times and high-resolution performance, is setting the stage for next-generation ePaper displays. But what exactly is electrowetting ePaper, and how does it work? Let’s explore the key principles behind this technology and its advantages in modern display applications.

What is Electrowetting ePaper Technology?

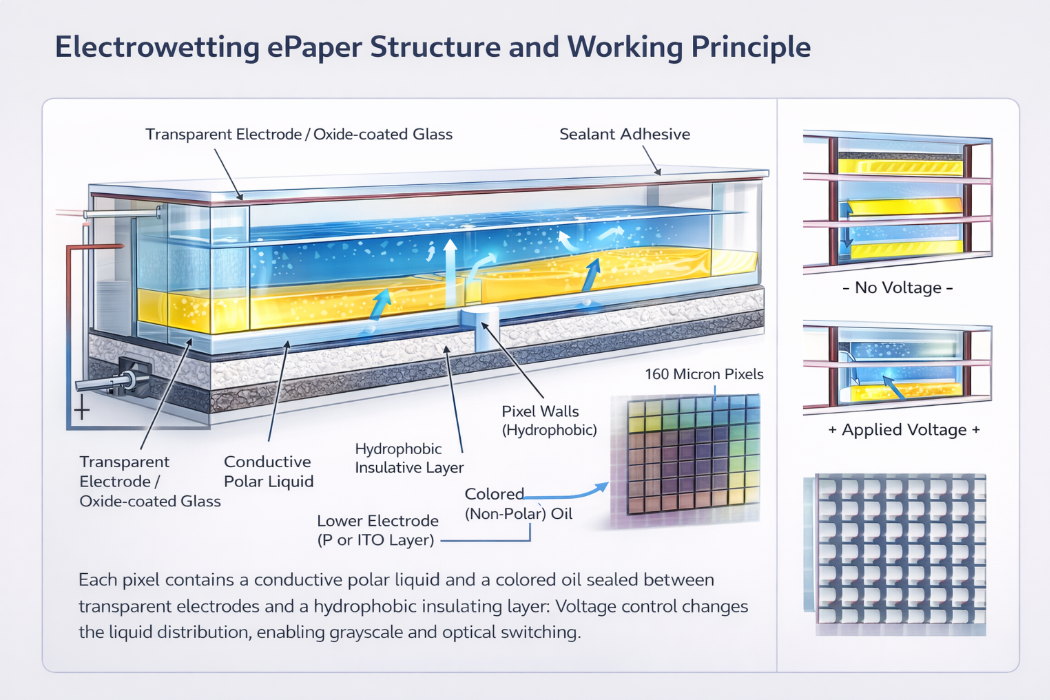

Electrowetting ePaper utilizes a unique display mechanism based on microfluidics, where two immiscible liquids—one polar and one non-polar—are confined within a sealed pixel structure. These fluids interact with an electric field to create vivid images with high contrast. The display module consists of two primary substrates: an upper substrate with electrodes and a lower substrate that contains a hydrophobic insulative layer and pixel walls. The interaction between the liquid interfaces and the applied electric field enables the control of the display’s visual content.

In an electrowetting system, the fluid within each pixel responds to electric fields, adjusting the position of the fluid interface to display information. When the electric field is applied, the polar liquid wets the surface more effectively than the non-polar liquid, creating different visual states for each pixel. This process is key to creating grayscale control, where the display’s brightness is adjusted by the movement of the fluids.

How Does Electrowetting ePaper Work?

Electrowetting ePaper uses an innovative two-phase fluid system within the display. Here’s a closer look at how it functions:

- The Pixel Structure: Each pixel is made up of a hydrophobic pixel wall and two layers of liquid—polar and non-polar. The polar liquid has a better wetting ability, allowing it to fill the pixel area, while the non-polar liquid is separated by the hydrophilic walls.

- Electric Field Application: By applying an electric field, the interface between the liquids is manipulated. The movement of the liquids within the pixels creates different optical states, switching between black and white (or other colors) depending on the electric field strength.

- Grayscale Control: The electrowetting system allows for fine control over grayscale by adjusting the amount of non-polar liquid within the pixel. This enables the display to show various shades between black and white, creating smooth transitions between pixels.

- Color Mixing: To achieve color displays, multiple basic monochrome structures are combined and layered vertically. This vertical color mixing approach offers superior color quality, unlike traditional ePaper technologies that use RGB color filters.

Advantages of Electrowetting ePaper

- Fast Optical Response: Electrowetting displays are known for their high-speed optical switching, with response times as quick as 10ms per pixel. This makes them well-suited for high-frame-rate video playback and dynamic content that requires fast visual updates.

- High Resolution and Reflectivity: Electrowetting displays have significantly improved performance in terms of resolution and reflectivity. The display uses colored ink that absorbs light, resulting in an optical system capable of achieving higher reflectivity—up to 1.5 times higher than traditional ePaper technologies. This leads to greater clarity and vivid imagery.

- Low Power Consumption: Like other ePaper technologies, electrowetting displays require minimal power. Power is only consumed when the display is being updated, and once the image is static, no energy is required to maintain it. This makes electrowetting displays ideal for battery-powered applications.

- High Contrast and Color: Electrowetting displays offer superior contrast, allowing the display to show sharp and vibrant content. The ability to achieve full-color displays through vertical mixing of colored fluids also enhances the visual appeal of the display, making it suitable for a wide range of applications.

SEEKINK’s Technology Direction in the ePaper Ecosystem

Electrowetting technology offers fast response in specific use cases, but they still face limitations in long-term stability, manufacturing maturity, ecosystem readiness, and cost efficiency for large-scale deployment.

SEEKINK focuses on electrophoretic e ink technology. It delivers bi-stable images, ultra-low power consumption, excellent sunlight readability, long service life, and strong supply-chain support, making it ideal for industrial displays, digital signage, smart terminals, and information panels.

Through close ecosystem collaboration and continuous optimization of system integration and reliability, SEEKINK provides scalable ePaper modules and customized e-ink photo frames solutions, helping customers accelerate product development with stable quality and long-term supply assurance.