Recently, Media journalists have visited SEEKINK’s headquarters & Factory in Jiangxi to witness firsthand how SEEKINK is redefining the “genes” of electronic paper.

“This is the magic of electronic paper,” explained Mr. Ziping Hu (VP | SEEKINK). “Electronic paper is a paper-like electronic display that looks almost identical to actual paper. For example common LCD screens, it can continuously refresh and change its content, while consuming only one-hundred-twentieth of the power of an LCD display. Devices such as the Amazon Kindle e-reader and Hanvon e-books are also ePaper products.”

Entering SEEKINK’s warehouse, Mr. Hu picked up a raw material for the electronic ink layer to demonstrate: millions of differently coloured ink particles encapsulated within capsules just 130 micrometres wide. Nearly 30 million such capsules are neatly arranged across a 0.48-square-metre aluminium plate. Above them lies a common electrode layer composed of transparent conductive film.

“SEEKINK processes approximately 50,000 e-ink layers monthly, primarily adding a drive substrate to provide an electric field for the ink particles,” Mr. Hu explained.

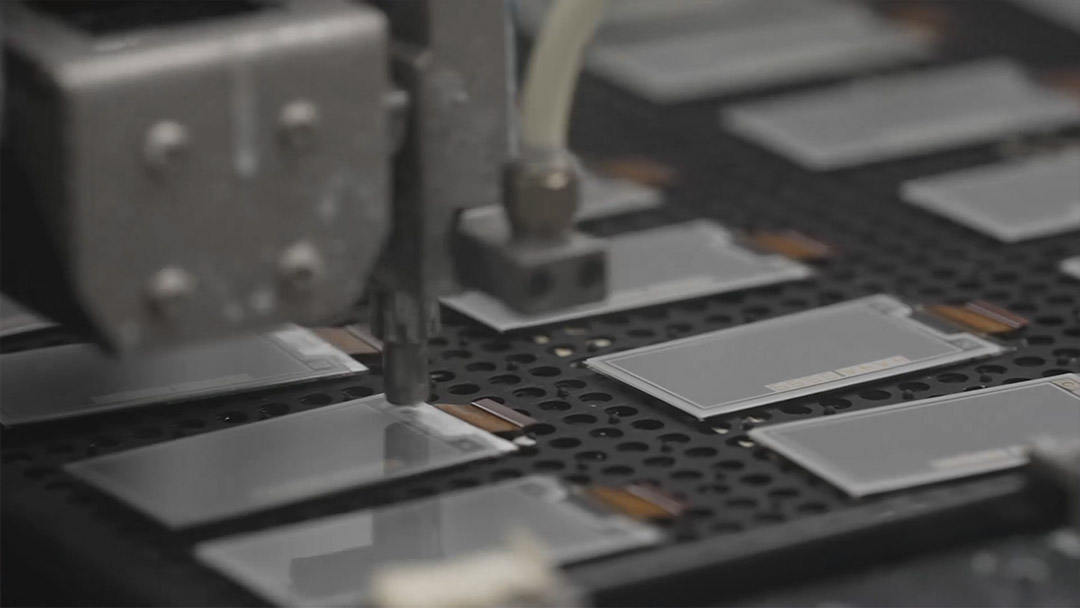

A single e-ink layer raw material is divided into smaller sections. After undergoing cleaning, drive layer attachment, encapsulation, and other procedures, it becomes a complete e-paper module ready for delivery to downstream e-paper device manufacturers. Annually, 100 million e-paper modules depart SEEKINK’s premises for overseas markets, including Europe and North America.

“Transitioning from ink layers to e-paper modules presents numerous technical challenges. Through sustained R&D efforts over recent years, we have mastered a suite of core technologies. With 135 patents to our name, we are redefining the fundamental characteristics of e-paper. This positions us to establish a robust competitive advantage within the fiercely contested market,” remarked Mr Shi (R&D Manager | SEEKINK).

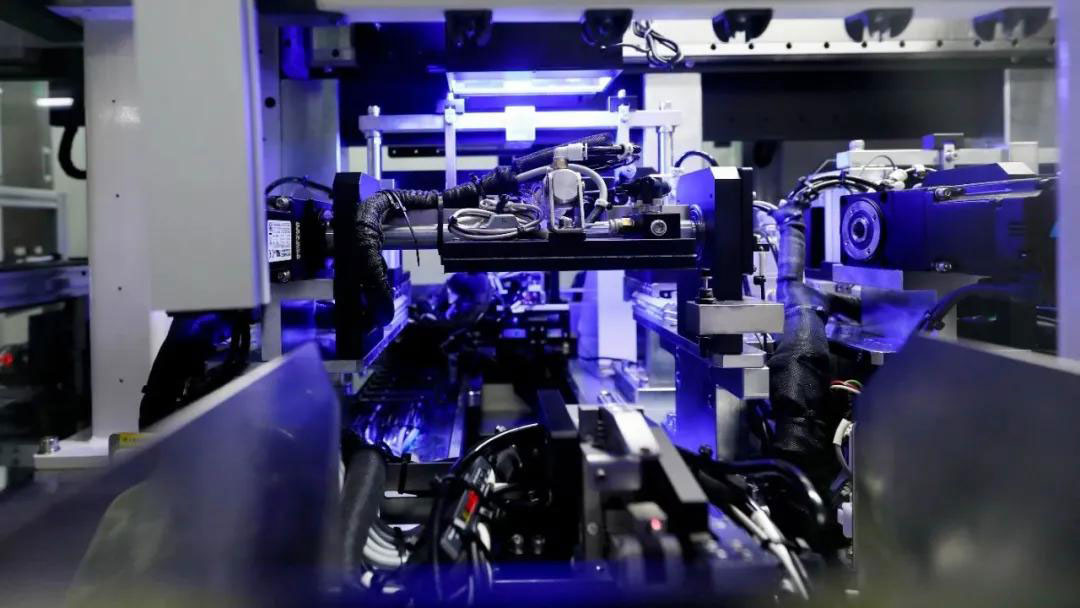

Over 20 fully automated production lines, capable of manufacturing more than 900 e-paper modules per hour, form the production heart of the entire enterprise. During the encapsulation stage, computer-controlled robotic arms precisely determine the coordinates and travel paths for each module without human intervention, maintaining an error margin of within 0.1 millimeters.

“The moisture-containing ink layer is highly sensitive to temperature and humidity, demanding more rigorous encapsulation techniques to maintain stable humidity levels. Consequently, we innovated by developing a more durable waterproof adhesive and secured a patent for our edge encapsulation structure, extending the warranty period from one to five years,” explained Mr. Zhong (PR Manager | SEEKINK).

Within the R&D centre, dozens of temperature-controlled chambers and platforms flicker with activity as over 60 technicians conduct waveform effect tests. “Each ePaper panel possesses its own unique characteristics due to variations in initial temperature and humidity. By meticulously calibrating distinct waveforms, we ensure every panel achieves optimal display performance across the 0 to 40°C range,” explained Mr. Zhong. He demonstrated a precisely calibrated module to reporters: after issuing a command via computer, the e-paper flawlessly rendered a complex image in just 23 seconds.

Technological innovation and process transformation have enabled SEEKINK’s business scale to expand continuously. SEEKINK has established marketing bases or subsidiaries in Germany, the United States, Vietnam, and other locations, with products sold worldwide. The innovative pulse from Jiangxi, China, shines through in electronic timetables at German bus stops, smart price tags in North American supermarkets, and warehouse display boards in Vietnamese factories.

To further advance e-paper drive technology, SEEKINK partnered with E Ink Holdings and BOE Technology Group in 2021 to establish the E-Paper Industry Alliance, attracting hundreds of enterprises to co-create an ecosystem map. Today, spanning semiconductor core component materials to brand manufacturers across diverse e-paper applications, the alliance is weaving a globally interconnected network of collaborative, mutually beneficial partnerships.

“Come on, we shall steadfastly pursue a green, low-carbon, and environmentally conscious path,” Mr. Hu affirmed. “We aim to evolve paper from “plant fibres” into “digital pixels”, sowing more green dreams upon the red earth!”

Contact SEEKINK:

Website: https://www.seekink.com/

LinkedIn: https://www.linkedin.com/company/seekink/

Business Contact: enquiries@seekink.com

Media & Membership Contact: contact@seekink.com